1. Introduction

The Inventory Management ERP project is designed to manage, monitor, and automate the stock control processes of an organization. It helps maintain accurate stock levels, track item movements, reconcile differences, and generate reports such as barcode labels and inventory statistics. This document provides an overview of the ERP Inventory Management modules so that we can understand how the system is structured and how it supports business operations.

2. Technology Stack

– Frontend: ASP.NET WebForms (C#)(ASCX, ASCX.CS, Design files, JavaScript)

– Backend: BAL (Business Access Layer), DAL (Data Access Layer), Factory classes

– Database: Microsoft SQL Server

3. Modules

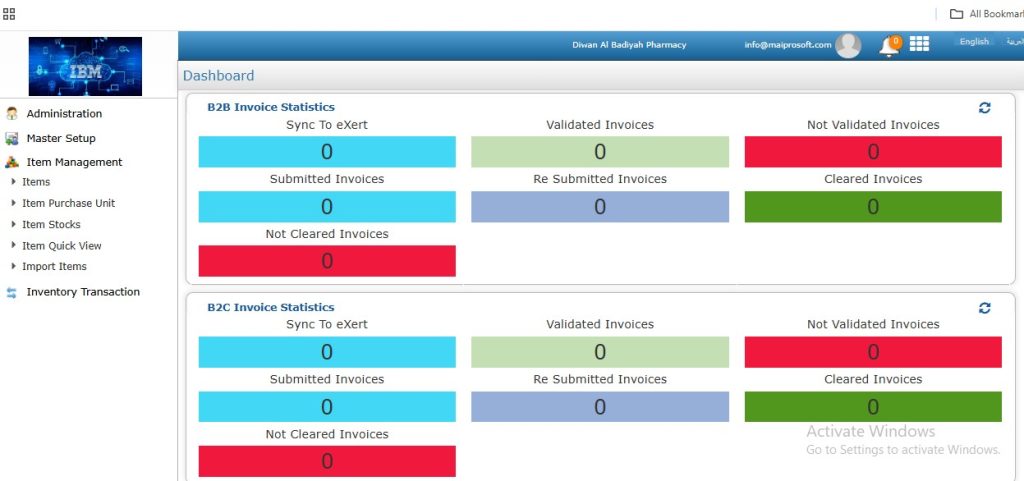

3.1 Administration

The Administration module is used to define the organizational setup and manage core information such as company details, user accounts, and warehouse information. This ensures that all inventory transactions are linked to structured organizational data.

3.2 Security Management

This module ensures that users can only access what they are permitted to. Roles are defined to control permissions, users are created and assigned to branches, and branch assignments help segregate access across multiple business units. It plays a critical role in maintaining data security and role-based access control.

3.3 Master Setup

The Master Setup module provides configuration options required for inventory operations. It allows defining categories, subcategories, product types, warehouses, and units of measurement. This ensures that inventory data is well-structured, consistent, and ready for use in transactions.

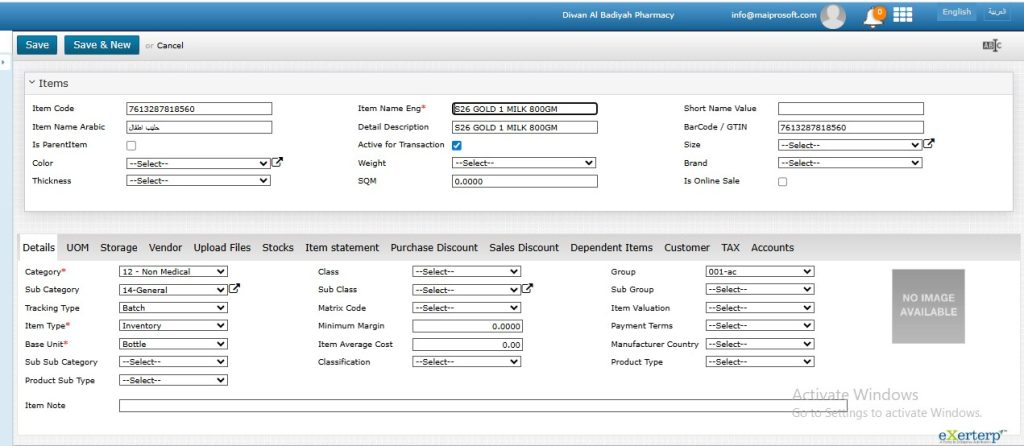

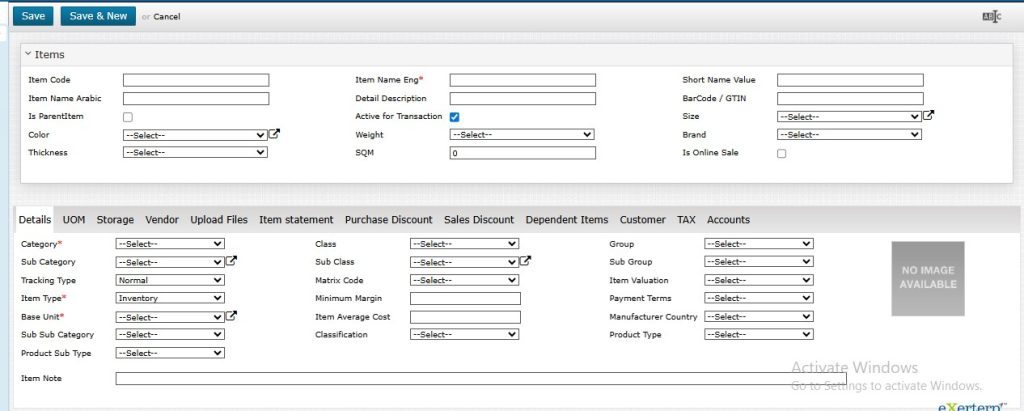

3.4 Item Management

The Item Management module focuses on the complete definition and tracking of items. It supports adding and editing items, assigning barcodes, importing bulk items, and viewing stock details for each item. By maintaining accurate product information, this module ensures smooth operation across the inventory system.

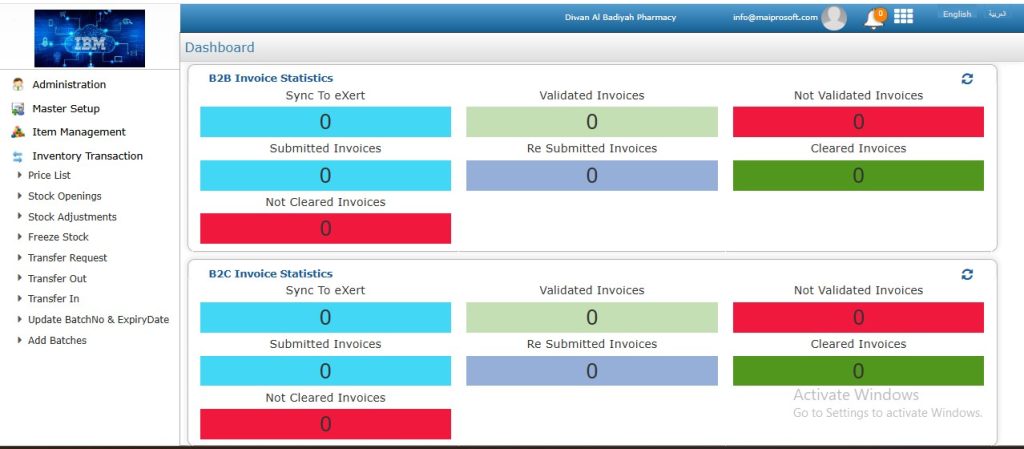

3.5 Inventory Transaction

The The Inventory Transactions module is the core of the system, handling all stock-related activities. It includes:

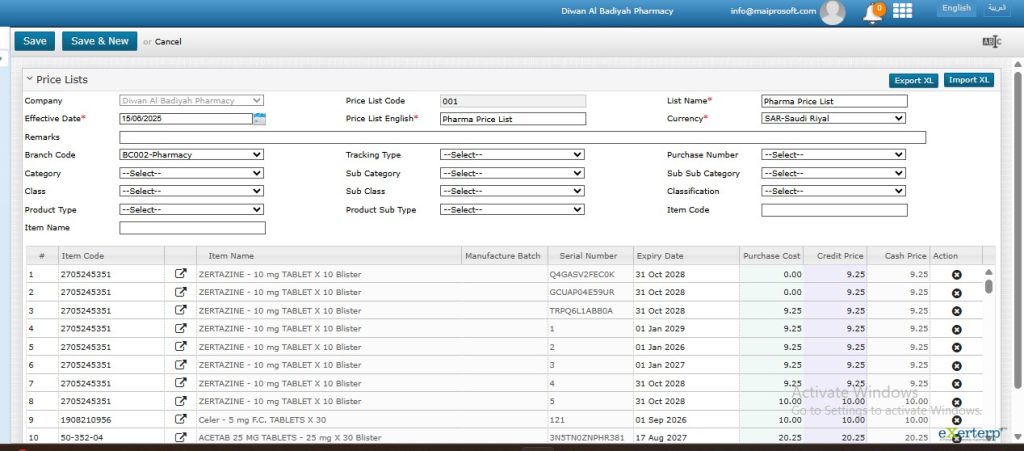

- Definition and management of price lists

- Entry of opening stock for warehouses

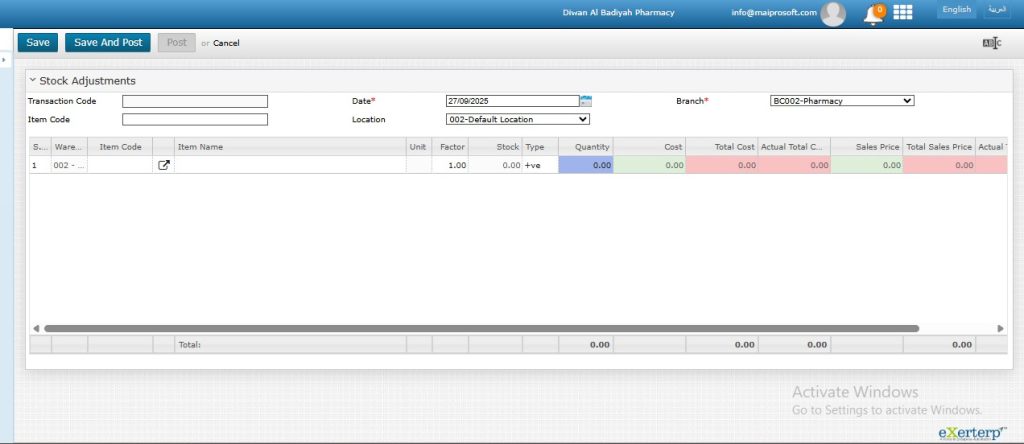

- Adjustments to correct discrepancies

- Stock freezing to lock current stock levels for auditing

- Reconciliation to match system stock with physical stock

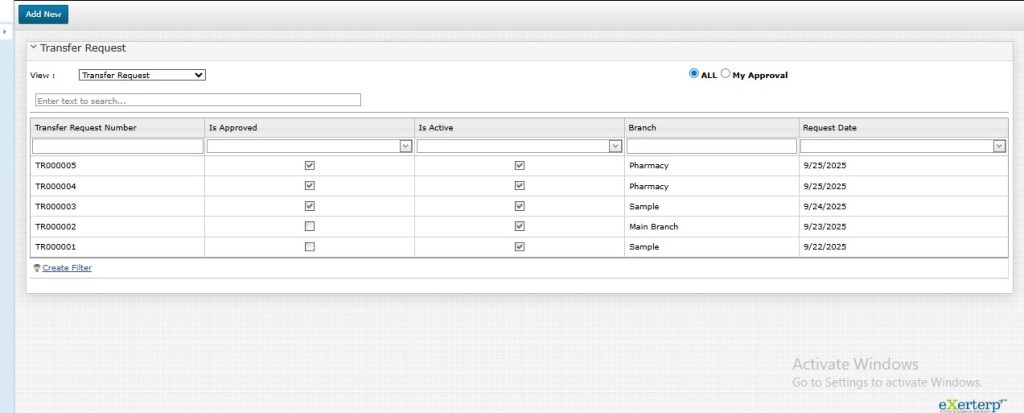

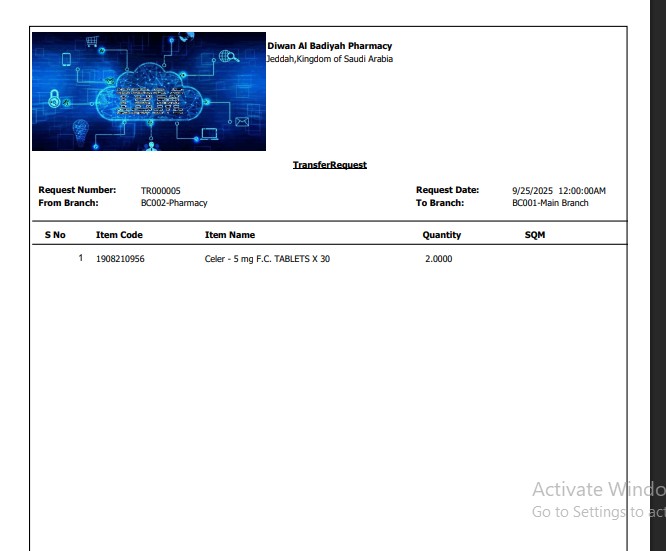

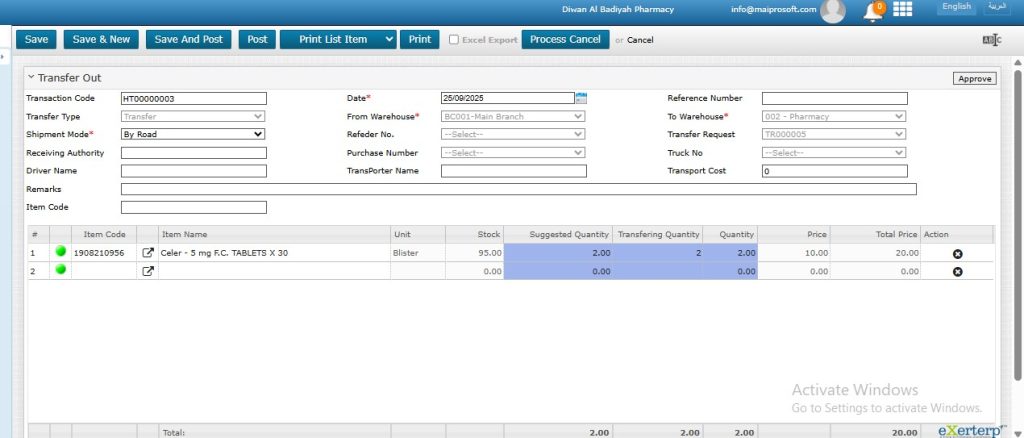

- Transfer requests, transfer-out, and transfer-in operations

- Updating batch numbers and expiry dates for sensitive items

- Adding new batches as needed

These processes ensure that stock is accurately tracked and controlled across the organization.

4. Why This ERP Inventory System?

This ERP Inventory System provides end-to-end control over inventory, from stock opening to reconciliation. It maintains accurate item, batch, and warehouse records while enhancing security through user roles and branch-based segregation. Built using industry-standard technologies such as ASP.NET WebForms and SQL Server, it ensures scalability and reliability. It also supports barcode-based tracking and structured reports, enabling organizations to monitor stock in real time.

5. What You Will Learn After Doing This Project

By working on this project, you will gain an understanding of how inventory processes operate in real organizations and how ERP systems are structured into modules and sub-modules. They will also learn how to build enterprise applications using ASP.NET WebForms and SQL Server, implement role-based security, and manage stock operations such as opening balances, adjustments, freeze, reconciliation, and transfers. Additionally, they will understand how to integrate barcode functionality within ERP systems for accurate and efficient stock tracking.